WHATS YOUR NEXT MOVE?

From Design to Testing, We Deliver Complete Engineering Solutions

SERVICES@FUTURE-SAFE.CO.UK

01562916506

Full Project Package

From CAD design to prototyping, testing, and reporting – an end-to-end solution tailored to your project.

Design & Simulation

Advanced SolidWorks + FEA simulations to validate strength, safety, and performance before build.

Prototype Package

Rapid prototyping (CNC & 3D printing) with professional reporting for validation and investors.

Why Future-Safe?

At Future-Safe, we combine engineering expertise with hands-on prototyping and testing to deliver solutions that don’t just look good on paper — they perform in the real world.

- Precision Design & Analysis – Our team uses advanced SolidWorks modelling and FEA simulations to predict performance, reduce risks, and optimise designs before manufacturing.

- End-to-End Capability – From 3D printing and CNC machining to mechanical and fatigue testing (tensile, shear, and impact), we cover the entire product development cycle under one roof.

- Proven Reliability – Every prototype and report we deliver is built to meet industry standards, giving you confidence for compliance, investor presentations, or product launch.

- Client-Focused Approach – Whether you’re a startup with a concept, or an established business scaling production, we adapt our service to your project goals, timelines, and budget.

- Standards Compliance Testing – Validation to ISO, ASTM, CE, and UKCA standards.

- Documentation & Reporting – Delivering comprehensive reports for regulatory approvals, patents, and investor presentations.

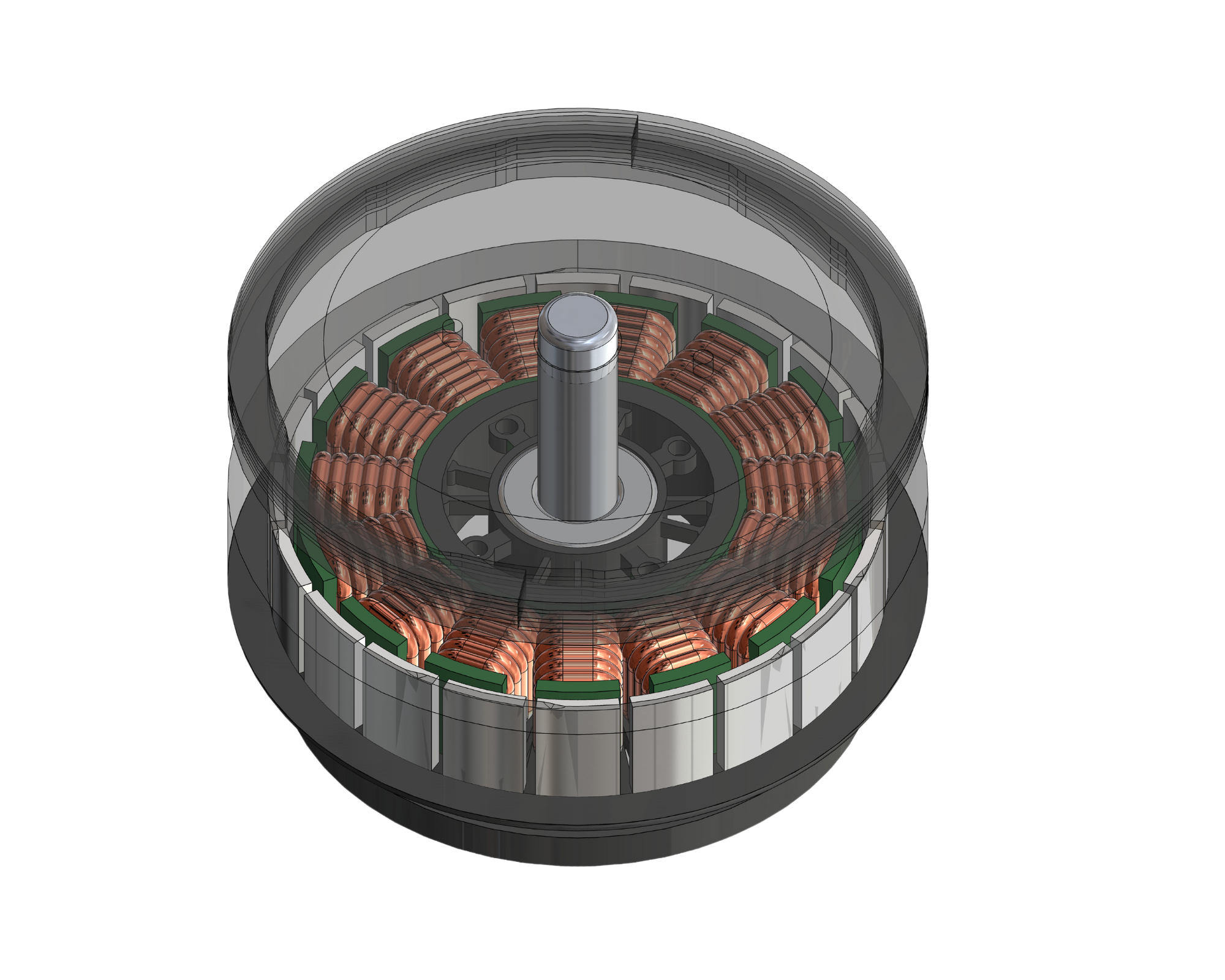

Aerospace Technology – Electric Motor Assembly

- Challenge: Engineer an efficient, compact motor with optimal cooling and durability for aerospace use.

- Solution: Used precision CAD modelling to design stator and rotor assemblies. Validated designs through fatigue, thermal, and vibration simulations. Manufactured components via CNC machining and additive processes for prototyping.

- Outcome: Successfully created a functioning prototype tested for performance under aerospace conditions.

- Impact: Improved energy efficiency, reduced weight, and supported greener propulsion systems in next-generation aerospace projects.

Dental Implants – Precision Engineering for Healthcare

- Challenge: Develop durable, biocompatible dental implants capable of withstanding high stress while ensuring patient safety.

- Solution: Applied advanced CAD design and FEA simulations to test implant stability and fatigue resistance. Materials were optimised for strength and corrosion resistance.

- Outcome: Delivered prototypes validated through mechanical testing, paving the way for clinical applications.

- Impact: Enhanced implant longevity and patient outcomes, meeting medical standards for regulatory approval.

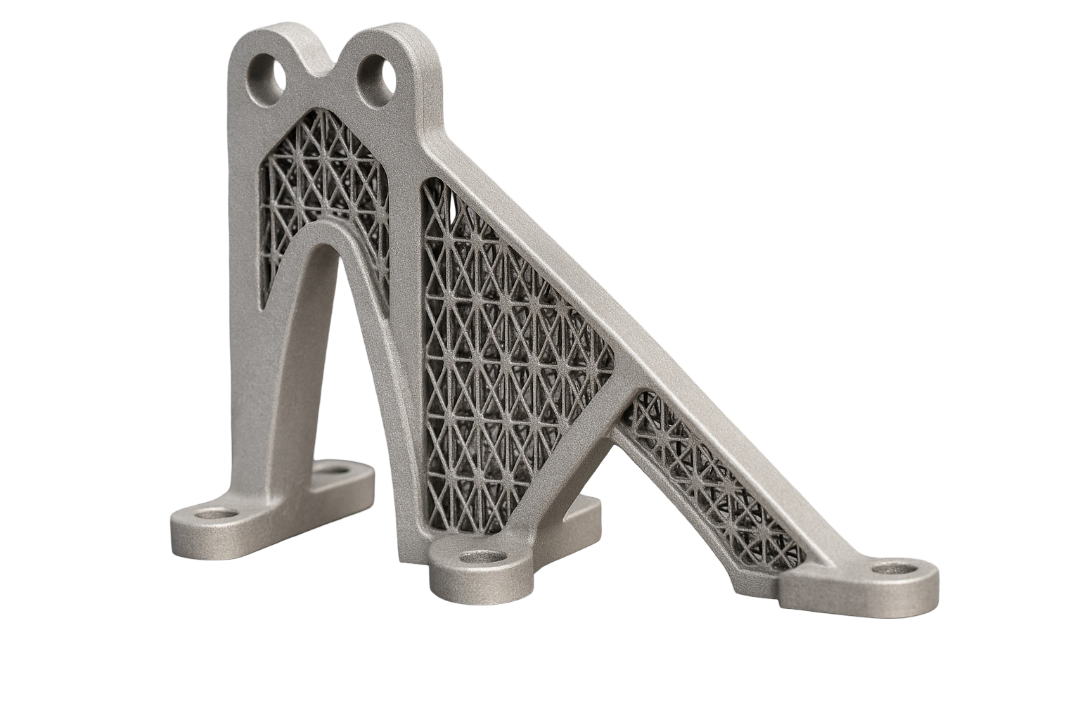

Additive Manufacturing – Lightweight Structural Component

- Challenge: Produce a lightweight yet strong aerospace bracket using additive manufacturing.

- Solution: Designed lattice-structured geometry in SolidWorks, simulated with FEA to minimise weight while maximising strength. Manufactured using advanced 3D printing and post-processed for precision.

- Outcome: Achieved a 40% weight reduction compared to conventional machining without compromising strength.

- Impact: Demonstrated how additive manufacturing enables cost savings, efficiency, and sustainability in aerospace applications.